Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Yunspire electroplating surface treatment

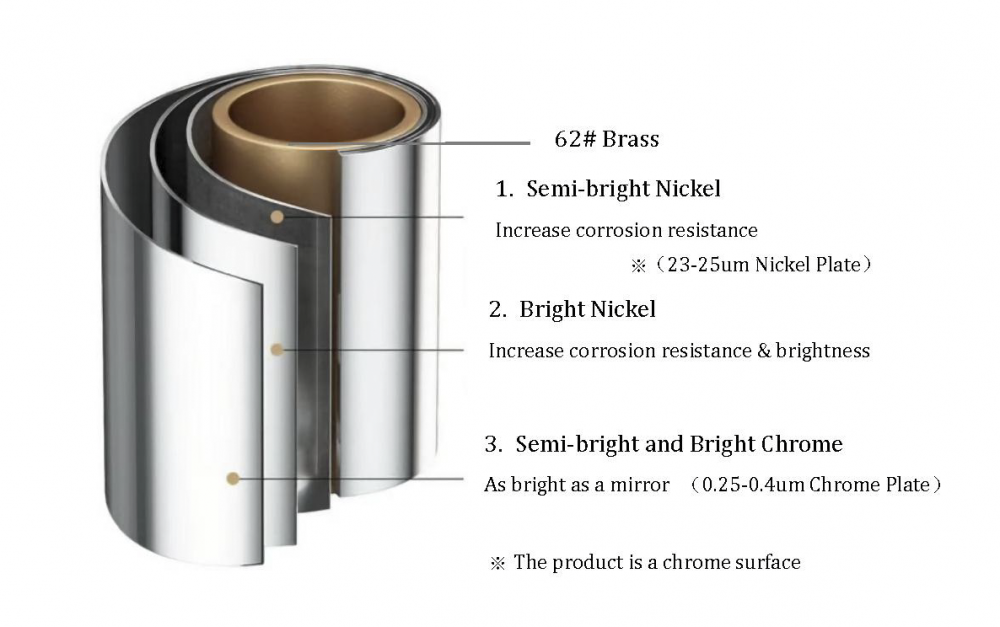

Nickel (semi-bright nickel + all-bright nickel), semi-bright chromium and all-bright chromium ensure a more compact combination of the tap surface coating and prevent them from peeling and corrosion.

The thickness of the electroplated coating

Nickel coating is 23-25 μm, chromium coating 0.25-0.4 μm, while the thickness of the nickel coating in general tap is 4-6 μm, and the chromium coating is 0.15μm. The thickness of the electroplated coasting decides the service life of the tap surface.

The principle is that the thicker the thickness of the nickel coating of the electroplated coating, the better the hardness and antiseptic power of the tap surface.

The super corrosion resistance through 200 hours of neutral salt spray test ensures to keep the brightness of the tap surface after using for a long time.

Want to know more about electroplating surface treatment, please click here:

https://www.tiktok.com/t/ZTR8wNGDL/?k=1

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.